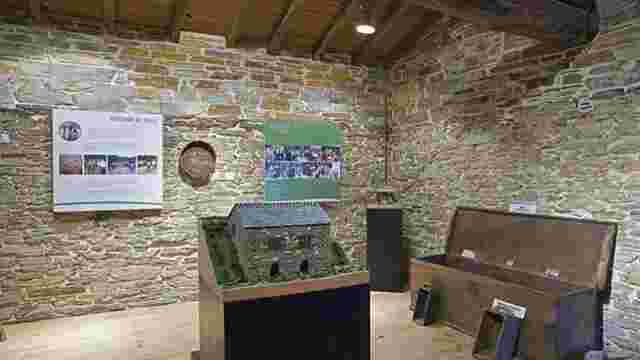

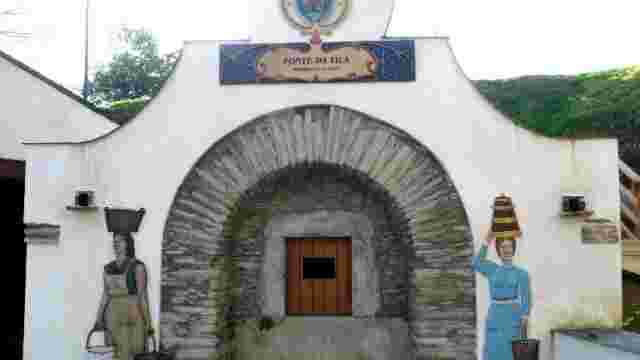

Museums and ethnography

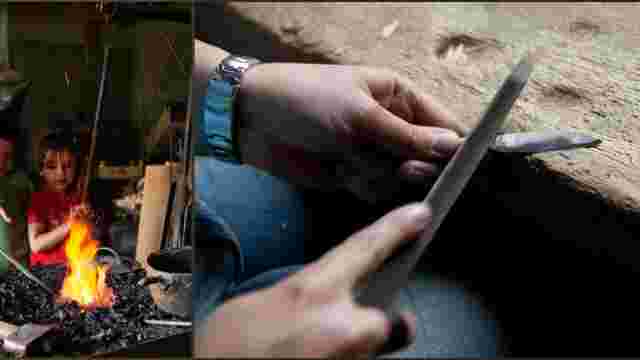

Juan Carlos Quintana" knife workshop

CQ is the signature used since the beginning of the 20th century by Camilo Quintana to "mark" his knives. Camilo manufactured cutlery in his workshop in Pardiñas, although he was born in A Veiga da Sarza, where he learned the trade of "ferreiro de mazo" from his father Manuel Quintana. We can document up to 7 generations of the Quintana family dedicated to working iron, from around the year 1700.

In 1995 Juan Carlos Quintana started a new workshop, also in Pardiñas, to manufacture knives and knifes, using the signature of his great-grandfather (CQ) to mark his products. The CQ Taramundi team is currently made up of Juan Carlos Quintana, José Manuel Cerdeira, Elvira Rodríguez and Erico Martínez. In 2001 José Manuel Cerdeira joined the workshop, first as an apprentice and later as a cutler. In July 2009 Elvira Rodríguez joined the workshop. Elvira is in charge of decoration and finishing, as well as customer service. In July 2016, Erico Martínez began his training as a cutler. In March 2017, he started making his first pieces ready to be sold.

The current work space has an approximate surface area of 200 m2, divided into 5 areas: processing room, forge, CNC room, engraving room and warehouse. Different materials are used to manufacture the different series and models: stainless steel, carbon, boxwood, heather, granadillo, cocobolo, bone, horn, silver, micarta, paper stone, ... applying different techniques, from the most traditional, learned from the best knife makers of Taramundi to the most avant-garde, such as laser cutting, CNC grinding or tempering in a controlled atmosphere furnace.

Some of the workshop tools have been developed to suit the needs of the work to be carried out (for example, the hydroventilated sander, so that the whole process of roughing the blade is carried out refrigerated to ensure that the hardness of the tempering is not affected by the machining process).

The final grinding of each blade is carried out manually, so that the planes that form the blade end practically at "0" so that the bevel is as discreet as possible. This makes the cut smoother and more precise.